Responsible innovation

As a textile company, we are keen to be aware of our responsibilities and, as far as possible, to help reduce the textile manufacturing footprint.

Responsible innovation

As a textile company, we are keen to be aware of our responsibilities and, as far as possible, to help reduce the textile manufacturing footprint.

Our objective is to impact the entire value chain and to help promote more eco-friendly, circular and resource-efficient products.

Xplor focuses particularly on:

- Durable products with a long service life

- Innovative designs for better recycling of textiles at the end of the product’s service life

- Eco-friendly materials (no materials that are harmful to the environment or health)

- Responsible production for employees as well as for the environment

- Long-term partnerships based on trust and fair trade

We always endeavour to be at the leading edge of legislation, industry standards and innovative solutions. We work with sustainability in the following areas:

DESIGN

MATERIALS IN PRODUCTION

PRODUCT SERVICE

PRODUCTION SETUP

DATA

Designed to last

Our products are renowned for quality of fit and functionality, as well as durability.

Specialist knowledge of material selection and design has made our products stand out in the marketplace for functional outerwear and durable products with a long service life have been our hallmark through all the years.

Our persistent work to develop the best and most durable products on the market is part of a strategic decision to ensure more resource-saving and sustainable manufacturing.

Design for the job

Workdays are very different, and every work function has its own requirements for functional outerwear.

Comfort, fit and working conditions must all be taken into account, and the outerwear must look professional day after day.

The employee’s everyday activities and environment must also be considered in the design process. Where employees work in environments with a lot of air particles, this must be considered in the choice of materials in order to ensure that the uniform does not look soiled.

Knowledge of the industry, selection of materials and thorough manufacturing ensure the right solution for the customer.

Design for recycling

In addition to increased durability, the products are designed to be re-used and recycled.

Specially selected materials and designs mean, for example, that the membrane in our jackets can be recycled with the rest of the jacket, and the reflectors and zips can be easily removed at the end of the product’s life cycle.

In the circular economy of the future, it will be important for products to be separated into separate materials.

Removable reflectors also make it possible to replace a worn reflector instead of replacing the whole jacket, thus extending the product’s service life.

Our products must last far into the future.

We are working on establishing partnerships across the value chain to ensure recycling of used textiles.

Designed for product optimisation

Xplor designs waterproof clothing with a view to optimised functionality and comfort.

This is achieved not only with a waterproof membrane with high water-column pressure, but also requires the taped material to last on the inside, and for it to be water-repellent after repeated wash cycles.

The impregnation is also important for keeping the surface dry so that the membrane beneath can perform optimally.

Xplor is licensed to use BIONIC-FINISH® ECO, the best and most eco-friendly impregnation on the market.

As well as being water-repellent and dirt-resistant, BIONIC-FINISH® ECO is also free of harmful chemicals such as formaldehyde, fluorocarbons and APEO compounds.

The treatment remains active (with correct use and maintenance) even after 20 wash cycles, which means there is no need for re-impregnation.

Instructions for correct maintenance (FAQ)

The combination of the right membrane, taped seams and a water-repellent finish enables the product to perform optimally, keeping the person wearing it warm and dry.

Designed for the weather

Xplor designs outerwear based on knowledge of how layering works.

If a jacket is to keep the wearer warm and dry, it is important to wear the right clothing under it.

The inside layer has to be breathable to enable the membrane in the jacket to perform optimally – and it is important for the surface to be dry.

The wearer’s pattern of movement also impacts the breathability of the membrane.

A fleece jacket is a good intermediate layer, as it is warming and breathable, and in an extra-cold climate this should be supplemented with thermal underwear.

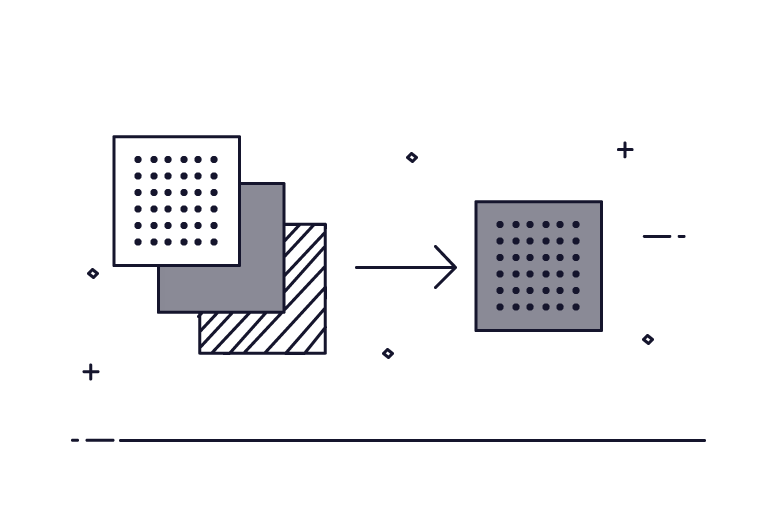

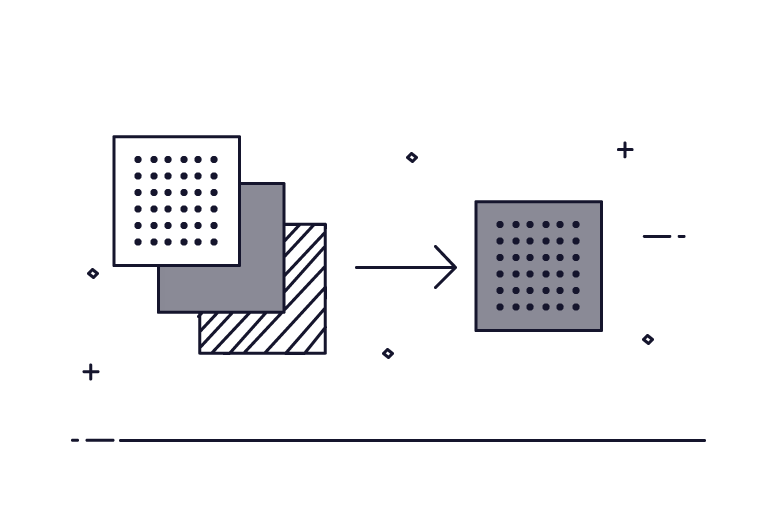

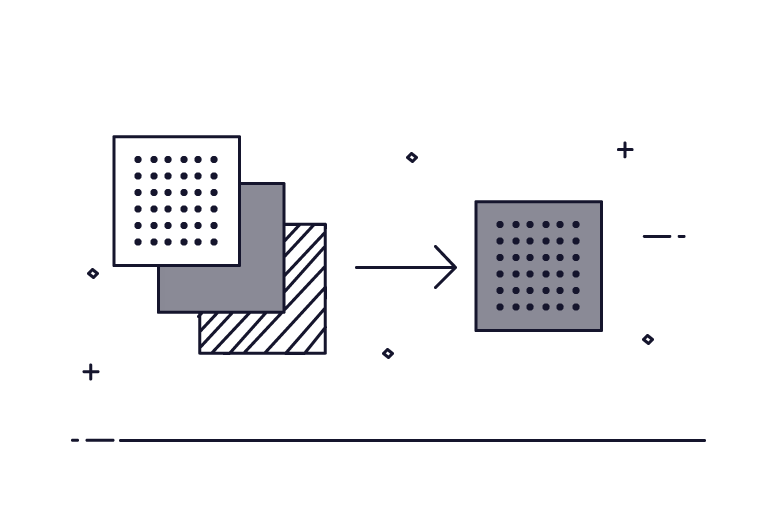

Reducing material variations in manufacturing

Xplor is keen to minimise the use of different textile materials, as it needs to be easy to separate the materials for recycling at the end of the product’s service life.

Our polyester zip can be melted down along with the other polyester materials that are used in the majority of our products.

Transparency in the use of materials

We are working to increase transparency with our products to make the constituent materials of the product easier to separate and recycle.

Designed to last

Our products are renowned for quality of fit and functionality, as well as durability.

Specialist knowledge of material selection and design has made our products stand out in the marketplace for functional outerwear and durable products with a long service life have been our hallmark through all the years.

Our persistent work to develop the best and most durable products on the market is part of a strategic decision to ensure more resource-saving and sustainable manufacturing.

Design for the job

Workdays are very different, and every work function has its own requirements for functional outerwear.

Comfort, fit and working conditions must all be taken into account, and the outerwear must look professional day after day.

The employee’s everyday activities and environment must also be considered in the design process. Where employees work in environments with a lot of air particles, this must be considered in the choice of materials in order to ensure that the uniform does not look soiled.

Knowledge of the industry, selection of materials and thorough manufacturing ensure the right solution for the customer.

Design for recycling

In addition to increased durability, the products are designed to be re-used and recycled.

Specially selected materials and designs mean, for example, that the membrane in our jackets can be recycled with the rest of the jacket, and the reflectors and zips can be easily removed at the end of the product’s life cycle.

In the circular economy of the future, it will be important for products to be separated into separate materials.

Removable reflectors also make it possible to replace a worn reflector instead of replacing the whole jacket, thus extending the product’s service life.

Our products must last far into the future.

We are working on establishing partnerships across the value chain to ensure recycling of used textiles.

Designed for product optimisation

Xplor designs waterproof clothing with a view to optimised functionality and comfort.

This is achieved not only with a waterproof membrane with high water-column pressure, but also requires the taped material to last on the inside, and for it to be water-repellent after repeated wash cycles.

The impregnation is also important for keeping the surface dry so that the membrane beneath can perform optimally.

Xplor is licensed to use BIONIC-FINISH® ECO, the best and most eco-friendly impregnation on the market.

As well as being water-repellent and dirt-resistant, BIONIC-FINISH® ECO is also free of harmful chemicals such as formaldehyde, fluorocarbons and APEO compounds.

The treatment remains active (with correct use and maintenance) even after 20 wash cycles, which means there is no need for re-impregnation.

Instructions for correct maintenance (FAQ)

The combination of the right membrane, taped seams and a water-repellent finish enables the product to perform optimally, keeping the person wearing it warm and dry.

Designed for the weather

Xplor designs outerwear based on knowledge of how layering works.

If a jacket is to keep the wearer warm and dry, it is important to wear the right clothing under it.

The inside layer has to be breathable to enable the membrane in the jacket to perform optimally – and it is important for the surface to be dry.

The wearer’s pattern of movement also impacts the breathability of the membrane.

A fleece jacket is a good intermediate layer, as it is warming and breathable, and in an extra-cold climate this should be supplemented with thermal underwear.

Reducing material variations in manufacturing

Xplor is keen to minimise the use of different textile materials, as it needs to be easy to separate the materials for recycling at the end of the product’s service life.

Our polyester zip can be melted down along with the other polyester materials that are used in the majority of our products.

Transparency in the use of materials

We are working to increase transparency with our products to make the constituent materials of the product easier to separate and recycle.

We stay up to date with new knowledge and technologies that can advance our industry

Your insights are valuable to us; please feel free to reach out if you see opportunities for improvement